High Quality Excavator Ripper, RSBM Manufacture!

As we all know, the excavator ripper is normally used in construction and demolition projects. It can help us save a lot of time and greatly improve our efficiency. However, As far as we know, many excavator masters are not very clear on how to use the excavator ripper. Today take a look at the structure, working principle and structural characteristics of scarifies, hoping to help those who do not know how to use them correctly.

1. The working principle of the excavator ripper:

The excavator ripper is connected with the main boom cylinder and the main boom, one end of the main boom is connected with the forearm fulcrum, the forearm is connected with the forearm cylinder and the ripper, and the ripper is connected with the ripper. Its characteristic is: the ratio of the distance from the support point of the forearm cylinder rod head to the forearm fulcrum to the distance from the forearm fulcrum to the ripper is 0.4-0.8. By shortening the arm length and increasing the arm thickness, the weight of the main arm and forearm is increased, and the hydraulic cylinder is added. Capacity to generate more power. Change the ratio of the upper and lower sections of the forearm fulcrum so that the rod head fulcrum of the forearm cylinder moves upward.

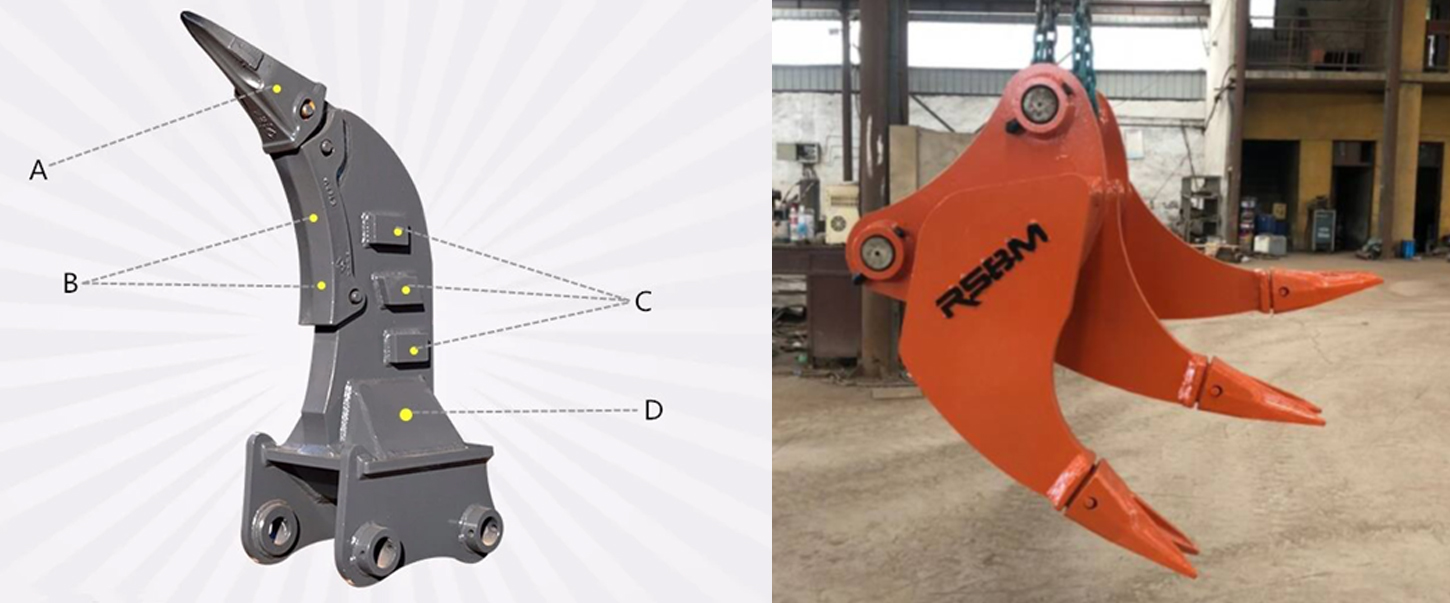

2. Structure:

A: Heavy-duty teeth

Fitted heavy-duty replaceable tooth to ensure the best results and wear resistance;

Usually single teeth,2 or 3 teeth for your choose

B: Nose protector

RSBM excavator ripper add a blade to protector ripper to prevent fracture, broken.

C: Wear resistant plate

NM400 material used in this plate to ensure the using life

D: Reinforce plate

Reinforced the whole structure, prevent the ripper body separate with ear plate

3. The structural characteristics of the excavator ripper:

3.1 The excavator ripper is used to connect the connecting plate and the lifting equipment. The connecting plate can connect the tamping machine and the lifting equipment, and is used on the excavator or other lifting equipment. The wear-resistant blade is fixed at the lower end of the connecting plate and is a key part of the side wall of broken gravel, sub-hard stone and weathered stone.

3.2 The wear-resistant teeth are detachably connected with the soil loosening bucket and wear-resistant blade of the excavator. The wear-resistant tooth has a triangular cross-section and is used to crush the bottom or middle of crushed stone, soft stone and weathered stone. There are several raised blades on the wear-resistant blade. The blade is a key component of the wear-resistant blade and plays a major role in crushing.

3.3 The blade section of the excavator loosening bucket is triangular. In order to facilitate the timely discharge of the broken stones of the knife part, the transition part between the two adjacent knife parts is also designed as a concave curved surface. The concave surface design allows the crushed stones to fall off the blade, enter the concave surface, and then discharge from the concave surface. In order to increase the contact area between the connecting plate and the receiving plate and enhance the bearing strength of the connecting plate, the following technical measures can also be taken: fix the inverted trapezoidal receiving block at the lower end of the connecting plate. plate.

Ripper is a sharp tool for breaking of hard earth, sub-hard stone and weathered stone. Convenient for buckets digging and loading. RSBM excavator ripper with strong body and high strength ripper tooth, strong digging and cut-in ability.

Choose RSBM, you can always enjoy long lifetime Excavator rippers with low maintenance!

Post time: Oct-26-2021